Sterility & Contamination Control with RTP Bags

In today’s biopharmaceutical industry, maintaining strict aseptic processing is essential to preventing contamination. Aptar Pharma offers rubber components for injectables packaged in Rapid Transfer Port (RTP) bags from top suppliers of RABS or isolator port systems, ensuring aseptic transfer to today’s fill-finish lines. Our RTP bags connect seamlessly to isolators and RABS, eliminating direct human contact during the transfer of rubber components and reduce the risk of contamination during fill-finish operations.

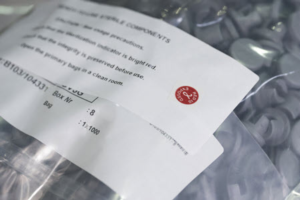

Aptar Pharma’s Ready-To-Sterilize (RTS) and Ready-To-Use (RTU) gamma-sterilized products come in polyethylene or Tyvek RTP bags, tailored to your specific process needs for clean, compliant component transfers of vial stoppers and syringe plungers.

Setting the Standard in Aseptic Transfers

The 2022 revision of the EMA GMP Annex-1 regulations emphasize contamination control and sterility in aseptic processing. Sections 4.3 and 8.47 recommend the use of isolators or RABS to reduce microbial and particulate contamination risks. To support Annex-1 compliance, Aptar Pharma provides advanced parenteral closure components in Rapid Transfer Port (RTP) bags, enabling safe, aseptic transfer that can help to streamline the approval processes.